Vehicle lifting systems for the maintenance of rail vehicles

Above-floor systems and underfloor systems for safe repair

We offer both above-floor systems (lifting jacks) and underfloor systems. Both systems allow for lifting not only individual vehicles but also complete vehicle sets without having to uncouple them.

If you require systems for maintenance but wish to avoid foundation work, then our systems are precisely what you need. They provide optimal maintenance access to the underside of rail vehicles.

We produce the control systems ourselves. Our safety PLC with integrated synchronization control fully complies with the latest DIN EN 1493 standard for vehicle lifting platforms.

Applications of our vehicle lifting systems

BÜTER Hebetechnik GmbH vehicle lifting systems are primarily used in the rail vehicle industry, but also find application in lifting trucks, buses, construction machinery, and tanks. They primarily serve the maintenance and servicing of these vehicles and ensure a safe and efficient workflow through their robust construction and precise technology.

Product details

Above-floor systems

Above-floor systems are either permanently installed or equipped with a chassis. The mobile lifting jack systems are available in all variants: as rail-mounted chassis or floor-mounted chassis, with or without drive. For lifting rail vehicles, the lifting jacks can be equipped with fixed or adjustable outriggers and corresponding load pads.

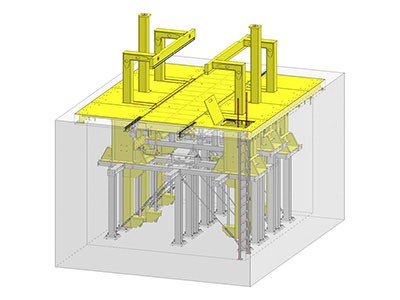

Underfloor lifting systems

Underfloor lifting systems can be designed for lifting individual components – such as single bogies – or entire vehicles. With our systems, you can realize highly efficient lifting lines where, by combining bogie and car body lifters, multiple bogies can be changed simultaneously without having to lower the vehicle in between.

Features of vehicle lifting systems

- Lasting Quality: Our constructions consist of high-quality components and are designed for a long service life.

- High Safety: Our systems are designed for maximum occupational and operational safety and comply with the latest safety standards.

- Efficient Workflows: Design your workflows with maximum efficiency by implementing lifting lines tailored to your requirements.

- Smooth Operation: We manufacture and stock almost all spare parts ourselves. Therefore, we deliver every spare part within the shortest possible time.

- Favorable Investment Costs: Upon request, we supply systems that require no or minimal foundation work (work pits).

- Expandable Systems: Our systems can be flexibly expanded and adapted to changing requirements.

Your benefits with a vehicle lifting system from BÜTER Hebetechnik GmbH

Tailored to your needs

We manufacture our lifting technology precisely to your specifications. Whether a standard product or a custom solution is required, we offer the tailor-made solution for all applications.

Production and Service from a Single Source

We manufacture almost every single component of our lifting tables directly at our facility. This allows us to guarantee you superior quality and prompt repair service.

Spare Parts Service

As we manufacture every lifting table assembly on-site, we keep many standard components in stock and can supply them to you quickly. Special components can be manufactured at short notice.

24 Months Warranty

We offer you not only the standard twelve-month warranty, but a full 24-month guarantee on our lifting technology. This ensures you are covered for the coming years.

Maintenance

Regular maintenance is crucial for the longevity of your lifting equipment. With our comprehensive maintenance service, we minimize downtime and maximize efficiency.

Sustainability

With our local manufacturing, we reduce transport, emissions, and traffic. We sustainably produce lifting technology through optimized production processes and manufacturing methods.

Examples of our vehicle lifting systems

Adjustable Load Clamp for Various Vehicle Types

Floor-mounted Trolley and Overhead Power Supply

Lifting Gantry with Adjustable Crossbeam

Lifting Jack 16 Tons

Lifting System with Bogie and Car Body Lifter

Overhead Spindle Drive and Spindle Protection with Bellows

Suspended Design with Electromotive Adjustment

Vehicle Lifting System 8 X 16 T