Manufacturer of Wheelset Turning Devices

Wheelset Turning Devices that leave nothing to be desired

Wheelset turning devices in rail technology enable the precise inspection of wheelsets as part of maintenance and inspection work on rail vehicles. The device is guided either in the rail foot of the track system or on a movable carriage within the inspection pit or under the elevated track, and supports itself on the running rail during the turning process.

You can couple several wheel-spinning devices together to rotate both wheelsets of the bogie synchronously. Our wheelset spinning devices can also be used as an underfloor testing device if they are equipped with an optional ultrasonic measuring instrument.

The wheelset turning devices are used by the rail vehicle industry for inspecting wheelsets.

Benefits of Our Wheelset Turning Devices

- Smooth Operation: Since the elevating work platforms can be perfectly adapted to your workflows, they reduce idle times and unnecessary effort.

- Flexible Application: The elevating work platforms can be used for various vehicles and applications.

- High Employee Acceptance: Your employees will appreciate the user-friendliness and high practical utility.

- High Safety Standards: Designed according to the latest DIN EN 280 for mobile elevating work platforms. Proven, intelligent safety features.

- Favorable Investment Costs: Thanks to high utility value and long service life, your investment pays off.

Features of the Wheelset Turning Devices

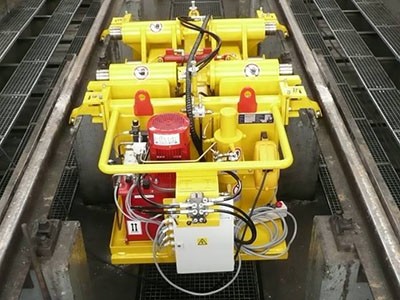

Our systems feature a particularly robust and durable design, ensuring high reliability. They support tandem operation based on the master-slave principle, which increases efficiency and flexibility.

The hydraulic rotary and lifting drive ensures precise movements and powerful applications. Power is conveniently supplied via a cable with a CEE plug, allowing for easy integration into existing systems.

Additionally, our devices can optionally be equipped with an ultrasonic measuring instrument, which supports precise monitoring and analysis. With their compact design and innovative solutions, they are versatile for use on various tracks and for different vehicle types.

Your Benefits with a Wheelset Turning Device

Tailored to your needs

We manufacture our lifting technology precisely to your specifications. Whether a standard product or a custom solution is required, we offer the tailor-made solution for all applications.

Production and Service from a Single Source

We manufacture almost every single component of our lifting tables directly at our facility. This allows us to guarantee you superior quality and prompt repair service.

Spare Parts Service

As we manufacture every lifting table assembly on-site, we keep many standard components in stock and can supply them to you quickly. Special components can be manufactured at short notice.

24 Months Warranty

We offer you not only the standard twelve-month warranty, but a full 24-month guarantee on our lifting technology. This ensures you are covered for the coming years.

Maintenance

Regular maintenance is crucial for the longevity of your lifting equipment. With our comprehensive maintenance service, we minimize downtime and maximize efficiency.

Sustainability

With our local manufacturing, we reduce transport, emissions, and traffic. We sustainably produce lifting technology through optimized production processes and manufacturing methods.

Examples of Our Wheelset Turning Devices

17.30370

Hydraulically Driven Conveyor Rollers

RSD as an Inspection Facility with Ultrasonic Measurement Technology

RSD Guidance in the Rail Profile

RSD Load Clamp for Rail Head

RSD on a Separate Powered Pallet Truck RSD on a Separate Powered Pallet Truck

RSD on Separate Transport Trolley, Non-Driven.

Tandem Configuration for Processing Bogies.