Manufacturer of Workshop Equipment

Complete Range for Optimally Equipped Railway Workshops

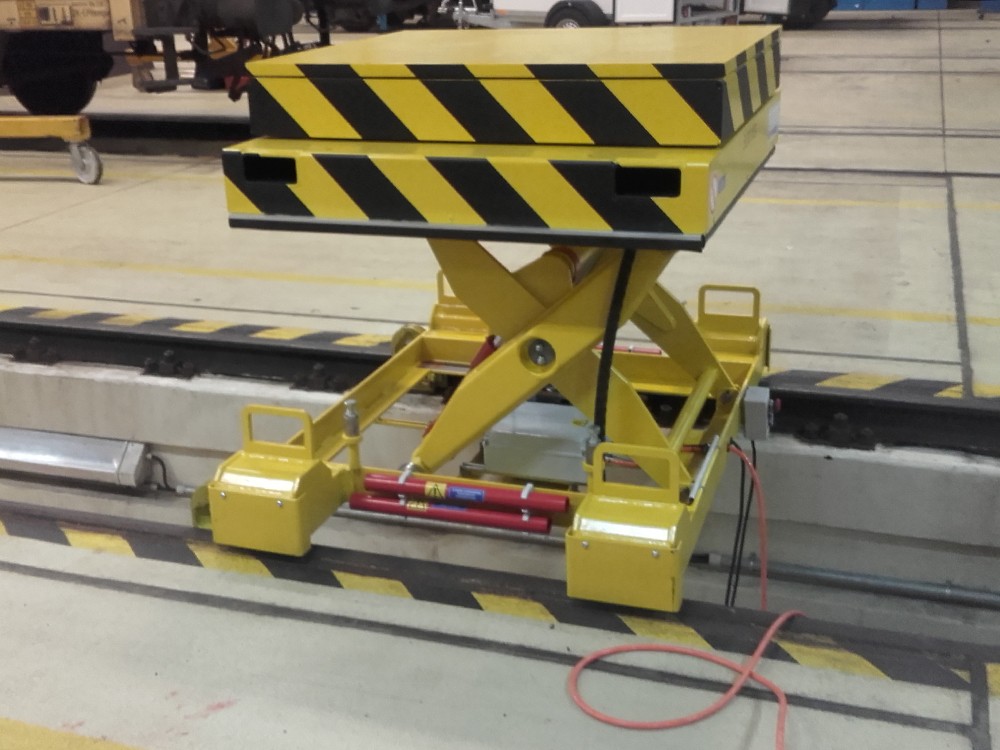

BÜTER Hebetechnik GmbH offers a comprehensive range of lifting tables and machinery for railway workshop operations: lift-and-turn devices, tilting devices, freight lifts, and lifting tables for wheelset, bogie, and component reconditioning. Additionally, hydraulic pit covers and lifting stairs are available.

The various products have one thing in common: quality. We emphasize in-house manufacturing of all critical components, a particularly robust yet space-saving design, and safe and ergonomic handling.

Our workshop equipment is mainly used in the rail vehicle industry to work on the various components – wheelsets, bogies, underfloor components, etc. – as well as to secure working pits.

Workshop Equipment Product Details

Lift-and-Turn Devices

Lift-and-turn devices can be used for bogie frames or even complete bogies.

Bogie Assembly Stands

For the assembly and disassembly of bogies, assembly stands with movable and telescopic lifters offer ergonomic and safe working conditions.

Wheelset Reconditioning

Lifting tables for wheelset reconditioning are available as single or double tables. They can be equipped with additional accessories, for example, with attachments for horizontal turning and rotation of the wheelsets. These lifting tables can also be linked together.

Pit Covers

Hydraulic pit covers seamlessly close unused side or central pits. This is recommended in confined spaces to prevent workplace accidents.

VARIO Stairs

The frontal stair access to work pits can be designed using a hydraulic lifting stair in such a way that it can be raised to a level surface, seamlessly flush with the hall floor. This creates an extended hall area without a fall hazard when the work pit or track is not in use.

Workshop Equipment Features

Our systems are characterized by a robust and durable construction, ensuring high reliability. They offer simple and ergonomic handling, maximizing user comfort.

With innovative solutions, our mobile systems can be used flexibly without requiring structural modifications to the foundations. Furthermore, they are expandable with various additional equipment, such as load beams, to further increase versatility.

Our safe lifting systems are equipped with hydraulic cylinders from our own production, ensuring precise and powerful movements. Furthermore, we offer customized solutions that are individually tailored to our customers’ needs to achieve optimal results.

- Smooth Operation: Perfect integration into your processes and low maintenance requirements ensure trouble-free operations.

- Sustainable Durability: Our designs exclusively use high-quality components to ensure a long service life.

- Low Maintenance Costs thanks to low-maintenance components.

- Efficient space utilization: Space-saving design with high power density.

Your Advantages with Workshop Equipment from BÜTER Hebetechnik GmbH

Tailored to your needs

We manufacture our lifting technology precisely to your specifications. Whether a standard product or a custom solution is required, we offer the tailor-made solution for all applications.

Production and Service from a Single Source

We manufacture almost every single component of our lifting tables directly at our facility. This allows us to guarantee you superior quality and prompt repair service.

Spare Parts Service

As we manufacture every lifting table assembly on-site, we keep many standard components in stock and can supply them to you quickly. Special components can be manufactured at short notice.

24 Months Warranty

We offer you not only the standard twelve-month warranty, but a full 24-month guarantee on our lifting technology. This ensures you are covered for the coming years.

Maintenance

Regular maintenance is crucial for the longevity of your lifting equipment. With our comprehensive maintenance service, we minimize downtime and maximize efficiency.

Sustainability

With our local manufacturing, we reduce transport, emissions, and traffic. We sustainably produce lifting technology through optimized production processes and manufacturing methods.

Examples of Our Workshop Equipment

Stationary Lift Table with Circumferential Box Bellows

Stationary Transfer Table

Support Frame