Coil Transport for the Steel and Aluminum Industry

Optimal Solutions for the Coil Transport of Steel and Aluminum

The coil transport of steel and aluminum is widely applied in the relevant industry. Typically, coil transfer is carried out by the automated storage and retrieval system (AS/RS), which stores and retrieves the steel and aluminum coils.

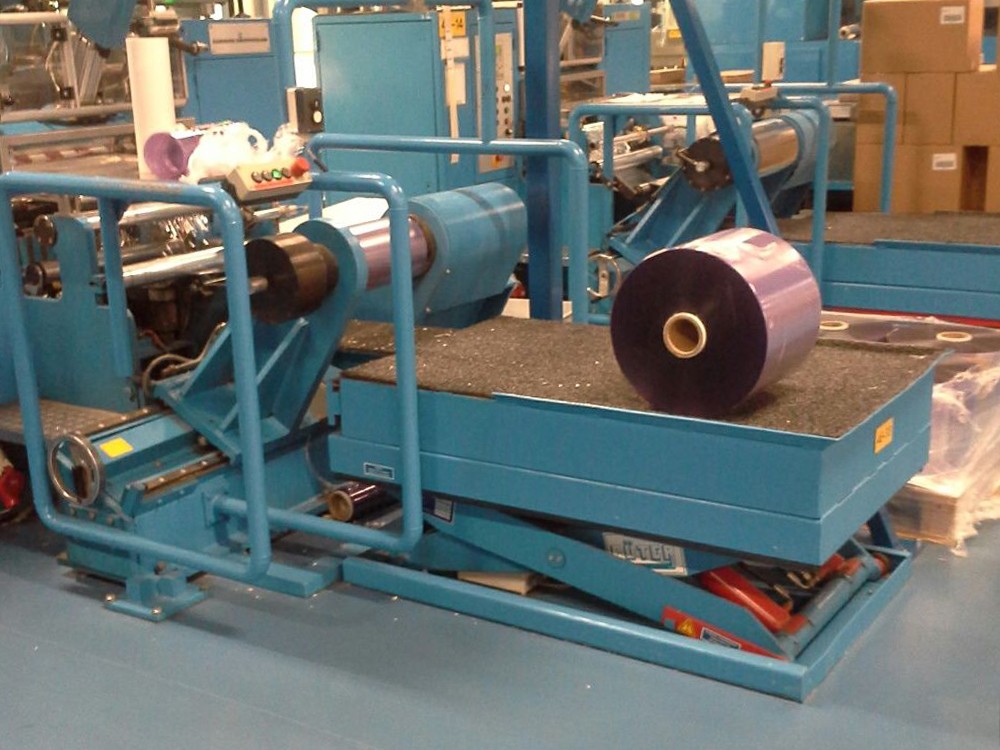

We offer both rail-guided vehicles and freely maneuverable models with all-wheel drive and all-wheel steering. These are equipped with various steering programs that enable extremely flexible use. Our coil transport vehicles for coil handling are optionally available with an integrated lifting device as lifting vehicles.

The coil transport vehicles are used in various industrial sectors, particularly in the steel and aluminum industry, as well as in the paper and plastics industry. They are designed for the safe and efficient transport of coils and are characterized by their robust construction and high load capacity.

Product Details

The OmniDrive drive concept enables precise positioning of the vehicles in all directions. In addition to front and rear-wheel steering, transverse travel, diagonal travel, or circular travel are also possible. The ingenious aspect: No steering movements are required at all; steering is achieved solely by controlling the direction of rotation and the speed of the wheels. This allows for every conceivable vehicle movement in the tightest spaces.

Various options are available for power supply:

- Wired Systems

- Battery Drives with Stationary Charging Stations

- Inductive Power Transfer (wireless and contactless)

In this way, the coil transport vehicles can be used very flexibly and are – in the case of battery drive or inductive transfer – easily accessible from all sides, without disruptive energy chains or similar.

Features of Coil Transporters

Our coil transporters are characterized by a robust and durable construction. They are equipped with plain-bearing solid rollers and low-maintenance plain bearings. The hydraulically driven scissor mechanism with hydraulic cylinders manufactured in-house ensures reliable operation. The electronic control system is programmed individually according to customer requirements.

- Smooth Operation: Perfect integration into your processes and low maintenance requirements ensure trouble-free operations.

- Long Service Life: Durable construction, built exclusively with high-quality components.

- Low Maintenance Costs: thanks to low-maintenance components.

- Durability: Robust construction, resistant to external influences.

Your Advantages with a Coil Transporter from BÜTER Hebetechnik GmbH

Tailored to your needs

We manufacture our lifting technology precisely to your specifications. Whether a standard product or a custom solution is required, we offer the tailor-made solution for all applications.

Production and Service from a Single Source

We manufacture almost every single component of our lifting tables directly at our facility. This allows us to guarantee you superior quality and prompt repair service.

Spare Parts Service

As we manufacture every lifting table assembly on-site, we keep many standard components in stock and can supply them to you quickly. Special components can be manufactured at short notice.

24 Months Warranty

We offer you not only the standard twelve-month warranty, but a full 24-month guarantee on our lifting technology. This ensures you are covered for the coming years.

Maintenance

Regular maintenance is crucial for the longevity of your lifting equipment. With our comprehensive maintenance service, we minimize downtime and maximize efficiency.

Sustainability

With our local manufacturing, we reduce transport, emissions, and traffic. We sustainably produce lifting technology through optimized production processes and manufacturing methods.

Examples of Our Coil Transporters

11.02130

11.23826

11.24172

11.24825

11.24951

11.25379

11.25516

11.26172