Wheelset Changing Systems for At-Grade or Elevated Track Systems

Wheelset Changing Systems are used for the removal of wheelsets in workshops

The Wheelset Changing Systems are used for the removal of wheelsets in workshops with at-grade or elevated track systems.

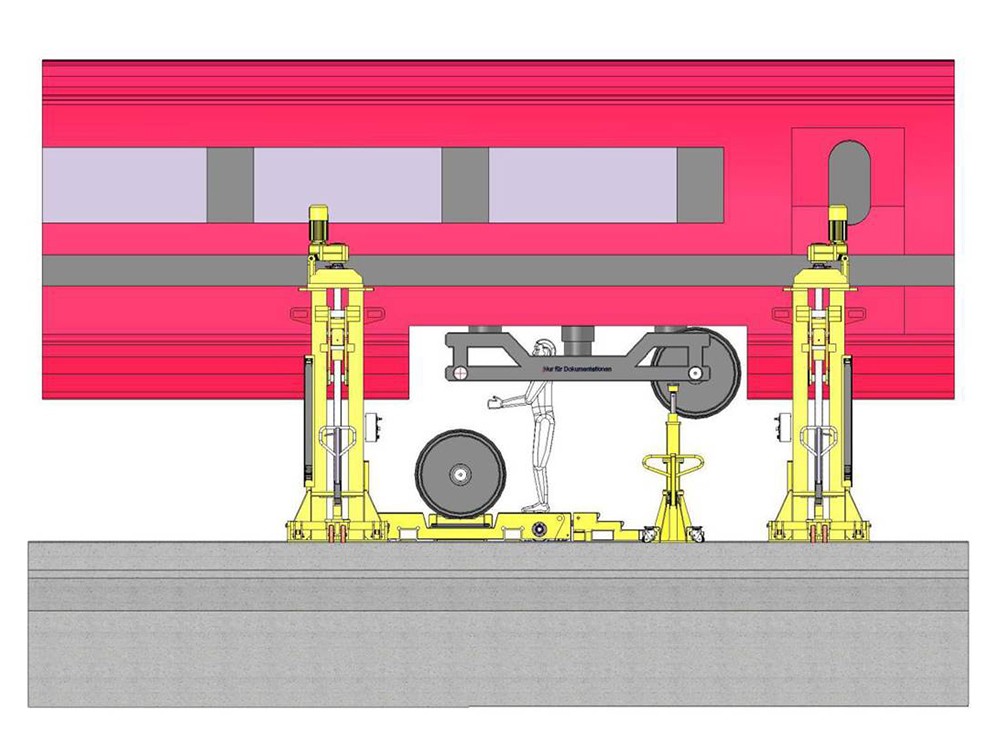

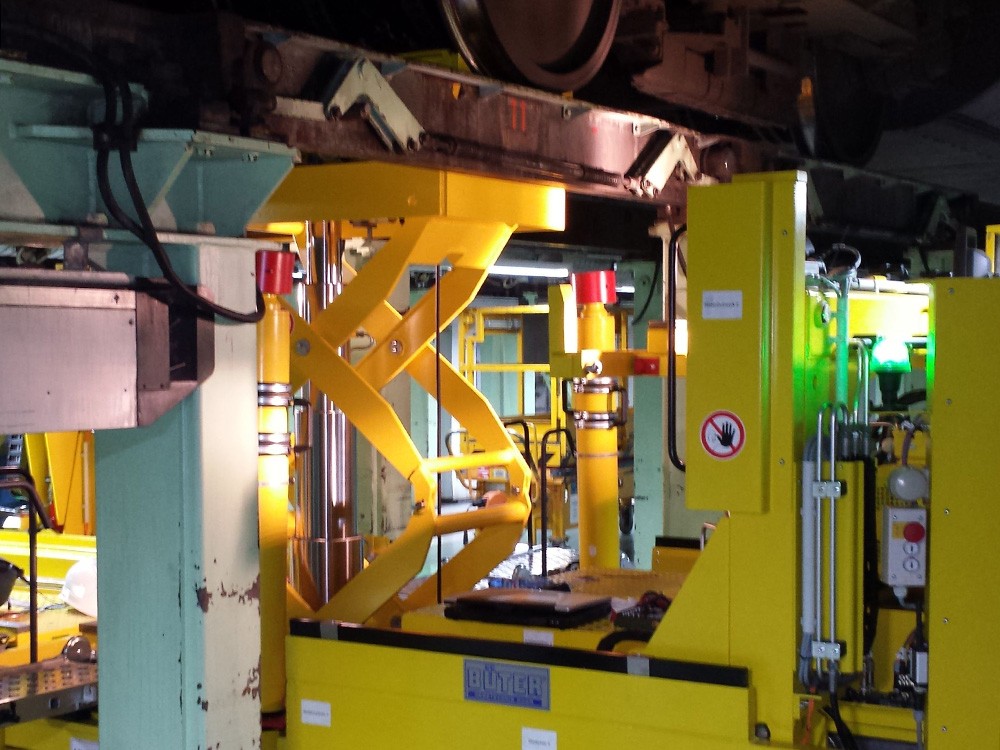

For at-grade track systems – pit tracks – rail-mounted changing vehicles are typically used in the track pit, which transport the wheelset beneath the vehicles to the removal station.

For elevated track systems, both stationary and mobile wheelset changing systems can be used. With stationary and mobile systems, the wheelset is transferred laterally at the track.

Our wheelset changing systems are used by leading railway companies and vehicle manufacturers for the efficient maintenance and servicing of rail vehicles. They offer high reliability, minimize downtime, and optimize maintenance processes.

Product Details

Our mobile system for elevated track systems with track bridges is the most flexible wheelset changing system and can also be retrofitted. This is easily placed onto the track with a forklift or a walkie stacker from BÜTER Hebetechnik GmbH (this requires track bridges). The mobile system for elevated track systems consists of the following components:

- Mobile Wheelset Changing System

- Freely Movable Walkie Stackers for Moving the Changing System

- Swiveling Track Bridges or Removable Track Bridges

- Mobile Support Stands

With this mobile system, wheelset changes can be performed simultaneously or sequentially at multiple positions on an elevated track system, without hindering other work on the vehicle.

With the help of additional components from BÜTER Hebetechnik GmbH, such as ball transfer units, other underfloor components like traction motors, etc., can also be changed.

Features of the Wheelset Changing Systems

Our wheelset changing systems, both mobile and stationary, are optimally adapted to existing track systems and are characterized by easy handling. Mobile solutions can be easily moved with forklifts. The sophisticated concepts are based on many years of experience with leading railway companies and vehicle manufacturers. The electronic control system is manufactured internally and programmed individually. Thanks to a wide range of additional equipment, the systems are versatile and expandable. Robust, durable constructions, high-quality hydraulic cylinders, and low-maintenance plain bearings guarantee maximum reliability.

- Efficient Workflows: Thanks to the perfect adaptation of our wheelset changing system to your workflows, you reduce unnecessary effort and ensure short downtimes.

- Employee Acceptance: The wheelset changing system is quickly understood and readily used by employees, as it is optimally adapted to their working methods. Additionally, high occupational safety is ensured by the sophisticated safety devices of our machines.

- Optimal Space Utilization: With systems from BÜTER Hebetechnik GmbH, optimal space utilization is a priority. They combine compact design with maximum lifting capacity and power density.

- Long Service Life: Our wheelset changing systems are designed to be particularly robust and built for a long service life.

- Short Downtimes: We stock and/or manufacture all spare parts ourselves. This ensures you receive your spare parts within the shortest possible time.

- Lower Construction Costs: We can supply you with wheelset changing systems which can be used without – or with only minor – foundation work. For example, our mobile systems.

- Flexibility: If your requirements change, we can quickly and flexibly adapt our system. This guarantees optimal utilization of your investment.

Your Advantages with a Wheelset Changing System from BÜTER Hebetechnik GmbH

Tailored to your needs

We manufacture our lifting technology precisely to your specifications. Whether a standard product or a custom solution is required, we offer the tailor-made solution for all applications.

Production and Service from a Single Source

We manufacture almost every single component of our lifting tables directly at our facility. This allows us to guarantee you superior quality and prompt repair service.

Spare Parts Service

As we manufacture every lifting table assembly on-site, we keep many standard components in stock and can supply them to you quickly. Special components can be manufactured at short notice.

24 Months Warranty

We offer you not only the standard twelve-month warranty, but a full 24-month guarantee on our lifting technology. This ensures you are covered for the coming years.

Maintenance

Regular maintenance is crucial for the longevity of your lifting equipment. With our comprehensive maintenance service, we minimize downtime and maximize efficiency.

Sustainability

With our local manufacturing, we reduce transport, emissions, and traffic. We sustainably produce lifting technology through optimized production processes and manufacturing methods.

Examples of Our Wheelset Changing Systems

Adjustable Gearbox Support for Drive Wheel Assembly

Extension of the Wheelset to the Transfer Position

Integrated Support Cylinders for Wheelset Change.

Load Claw Retracted

Lockable Track Bridges and Mobile Support Gantry

Mobile Pedestrian Stacker for Wheelset Replacement and Transport

Mobile Pit Cover and Mobile Pit Basin

Mobile RSW Deployed in Track Pit